Inexpensive system that reduces the amount of wood waste significantly.

The Finninno Edge Mould system is a new, inexpensive solution for the production of precast concrete sections. The system reduces the amount of wood waste at the precast section factory significantly. The Edge Mould System is available in two different heights.

1) Finninno Edge Mould System 250/430

250 - 430 mm high system for the production of facade elements, floor and balcony slabs and reinforced concrete piles

2) Finninno Edge Mould System 400/600

400 - 600 mm high system for the production of beams, pillars and facade sections

More detailed information

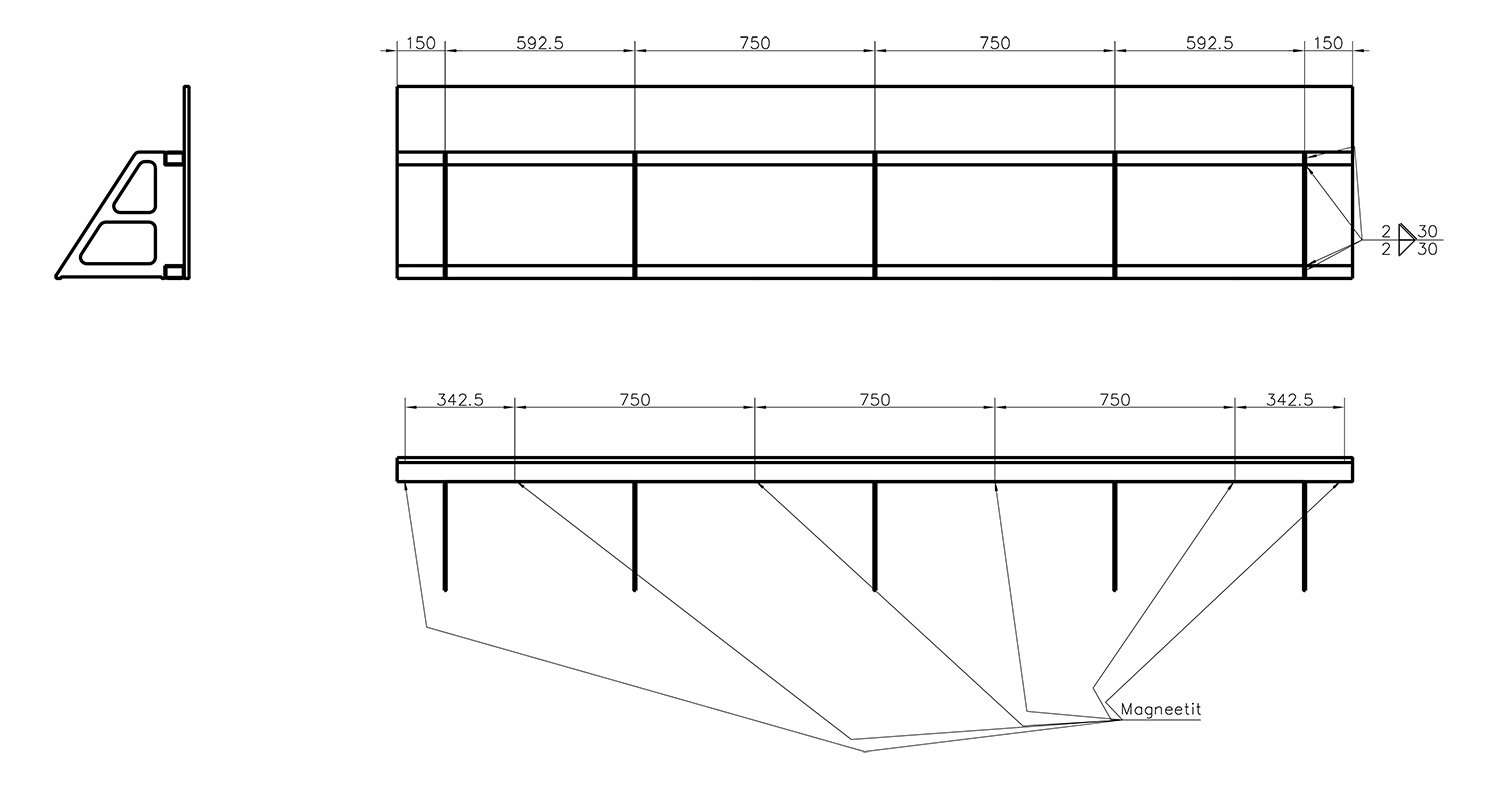

- Edge Mould System 400/600: supporting of edges with magnets at a pitch of 750 mm

- Edge Mould System 250/430: supporting of edges with magnets at a pitch of 1000 mm or 750 mm

- the magnet type is a standard edge magnet with a minimum capacity of at least 1,600 kg equipped with eccentric mounting, for example model Teräskari AM-1101B or equivalent

- also Elematic Push Button type magnet is suitable for the edge mould system when mounting plates suitable for these magnets are used; such as model Elematic (item number P 429204)

- supporting of moulds from the top edge is not required

- 15 mm thick birch plywood or combination plywood has been used in the calculation of the mould.

The delivery includes

- diagonal supports and pipe beams according to the 3D image (the figure shows edge mould system 400/600) are delivered separately with welding instructions (weld seams a2 30 mm)

- metal parts without surface treatment

- plywood is fastened to the pipe beams with, for example, Flugel drilling screws (e.g. Würth Flugel galvanised drilling screw 4.2 x 32, AW20 ZNC, item number 0219114232); in addition, plywood can also be fastened with double-sided tape (e.g. Etra Oy, Astorplast 11343 25/25 mat tape, sales code 40319420000) or using adhesives and sealants (e.g. Sikaflex 221)

- metal parts for 20 edge moulds (L = 2.985 m), metal parts for 10 edge moulds (L = 6 m) or metal parts for 5 edge moulds (L = 12 m).

The plywood, magnets and fasteners are not included in the delivery.

Easy and inexpensive solution for the production of precast concrete sections

- reduces the amount of wood waste significantly

- two different heights for different uses.