Precast concrete elevator shaft moulds with extreme dimensional accuracy enable easy installation and faster work steps, and ensure that construction work at the site is sure to run smoothly.

The elevator shaft mould is a cost-effective and fast way to cast high-quality concrete sections both in precast concrete section factories and at construction sites. It eliminates unnecessary production steps and significantly improves production efficiency as compared to other production methods. A single mould can produce as many as three precast concrete elevator shaft sections in just 16 hours, and 3,600 elevator shafts per year.

The same elevator shaft technology can be utilised in the manufacture of other shaft-like sections, such as bathroom sections.

The high-quality moulds designed by us are manufactured in Kotka, Finland, and they have been used by the construction industry in Finland and Russia since 2002.

We deliver technology transfer packages world wide, don't hesitate to contact us!

Why the Finninno precast concrete mould technology package is the perfect turnkey solution for your steel workshop?

Benefit from Finninno’s 30 years experience in the pre-cast concrete.

Our products are internationally tried and tested no need for you to develop your own mould industry technology.

Instantly have access to all the fabrication drawings you need to start. Future mould drawings from our designers.

Training and support during start of production.

You know your market! Quickly develop sales using our technology produced by you.

Details about the precast concrete elevator shaft mould

Investment that will pay itself back quickly

The payback period of the elevator shaft mould is about 40 production days, in other words only two months, when three elevator shaft sections are cast in one working day.

Finninno Elevator Shaft Mould saves time, costs and resources

1. Only one full section per floor

No more four separate walls that need to be connected to each other. Fewer tools, work stages and machines are needed, which also shortens the time taken by the work.

2. Easier work for elevator installers

A precisely measured, ready-made elevator shaft makes the work of elevator installers smoother, and the need for extra adjustment is eliminated. Fluent work saves time and resources.

3. Work runs smoothly in a clean environment

When there are fewer installation supports, there is more space available to work in staircases or stairs, and the work environment remains tidy.

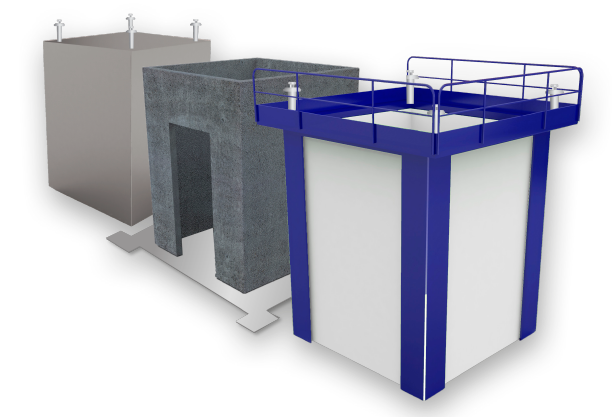

Inner mould, product on the concreting base, and outer mould. The height of the mould is normally about 3 metres, depending on the height of the floor and the needs of the customer. The width and depth of the mould can be customised according to the customer's needs. The maximum dimension is 4 metres per side.